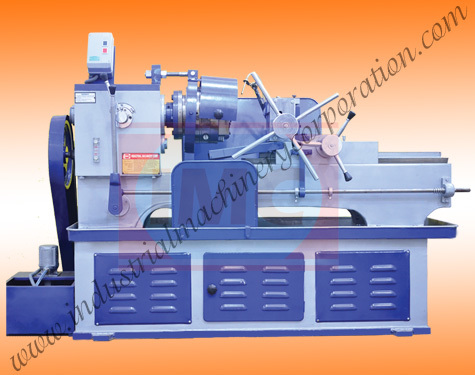

Bar Threading Machines

Bar Threading Machines Specification

- Voltage

- 415 V

- Frame Type

- Rigid Welded Frame

- Noise Level

- 75 dB

- Accuracy

- 0.1 mm

- Control System

- Manual & Electric Panel Control

- Machine Type

- Rebar Threading Machine

- Motor Power

- 5 HP

- Power Rating

- 5 HP / 3.7 kW

- Features

- Heavy Duty, Portable, Reliable Clamping, Fast Setup

- Frequency

- 50 Hz

- Lubricating System

- Automatic Lubrication

- Product Type

- Bar Threading Machine

- Technology

- Mechanical Reinforcement Cutting & Threading

- Power Source

- Electric

- Power

- 5 HP

- Pressure

- Hydraulic operated, adjustable upto 15 MPa

- Surface Treatment

- Powder Coated

- Dimension (L*W*H)

- 1250 mm x 480 mm x 960 mm

- Weight (kg)

- 480

- Usage & Applications

- Threading of TMT Bars, Rebars for construction industry

- Safety Mechanism

- Emergency Stop Button and Guarding Covers

- Bar Material Compatibility

- Carbon Steel, Alloy Steel, TMT Rebars

- Transportability

- Wheeled Base for Easy Transportation

- Tool Holder Type

- Adjustable

- Power Consumption

- 3.7 kW/hour

- Packing Type

- Export Standard Wooden Box

- Standard Accessories

- Threading Dies, Clamp Set, Wrenches

- Main Shaft Speed

- 62 rpm

Bar Threading Machines Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 30 Days

About Bar Threading Machines

Bar Threading Machine

The Bar Threading Machine is use to cut the external threads on the bar with the help of Tangential chaser. Bar Thread cutting Chaser is use as a cutter in machine. Bar remain still, Die-head rotates. Different types of threads can be cut on the bar such as BSW, NPT, UNF, METRIC, UNC, ACME, BSF Threads etc.

Such a company will offer you the amenity of customization, wherein the bar thread cutting machinery will be designed and fabricated as per your specifications. These can vary on aspects such as saddle movement, range of spindle speed, capacity , the number of units a it can produce in an hour and the requirement of power to operate the machinery.

As is the case with most bar threading machinery, this one too works with sub parts such as saddles, aprons and beds. These are all designed and fitted in such a manner that they provide hassle free operation and require minimal attention, post purchase. This not only ensures actual value for money, but also reduces the time spent on regular maintenance and servicing.

Range of IMC Bar Threading Die-Head.

- 1/4" to 1"

- 3/8" to 1.1/2"

- 1/2" to 2.1/2"

|

Model |

1/4" to 1" (Bed Type) |

3/8" to 1.1/2" (Bed Type) |

1/2" to 2.1/2" (Bed type) |

|

Saddle Movement |

10" |

10" - 12" |

12" - 16" |

|

Spindle Speed Range |

60-90 |

60-90 |

60-90-120 |

|

Number of Spindle Speed |

2 |

2 |

3 |

|

Threading Capacity |

1/4" to 1" |

3/8" to 1.1/2" |

1/2" to 2.1/2" |

|

Production per Hour |

60-80 |

60-80 |

70-90 |

|

H.P. Required |

3 H.P. |

3 H.P. |

7.5 H.P. |

|

Lead Screw |

Optional |

Optional |

Optional |

|

Weight (KG) Aprox. |

500 |

550 |

990 |

Versatile Material Compatibility

Engineered to process Carbon Steel, Alloy Steel, and TMT Rebars, this threading machine provides adaptive functionality for a variety of construction and reinforcement needs. The adjustable tool holder makes quick setup possible for different bar sizes and materials, contributing to efficient project workflows in multiple industrial scenarios.

Optimal Safety and Durability

With integrated safety features including an emergency stop button and comprehensive guarding covers, operator security is prioritized. The frame is rigidly welded and powder coated, offering longevity and resilience against corrosion. An automatic lubrication system enhances the machines reliability and minimizes maintenance requirements.

Efficient and Accurate Performance

Delivering precise threading accuracy of 0.1 mm at a main shaft speed of 62 rpm, the machine is engineered for consistency and repeatable results. Hydraulic operation ensures stable pressure up to 15 MPa. Users benefit from fast setup, reliable clamping, and a noise level not exceeding 75 dB, making it suitable for both indoor and outdoor construction sites.

FAQs of Bar Threading Machines:

Q: How does the Bar Threading Machine handle different types of steel bars?

A: The machine is compatible with Carbon Steel, Alloy Steel, and TMT Rebars. Its adjustable tool holder adapts to various bar diameters and materials, ensuring versatility in threading different steel types for construction applications.Q: What safety mechanisms are incorporated in this machine?

A: For enhanced operator safety, the machine is equipped with an emergency stop button and protective guarding covers. These features help prevent accidents during operation and maintenance.Q: When should the hydraulic pressure be adjusted, and how is it controlled?

A: Hydraulic pressure should be adjusted according to the material and threading demands. The machine allows pressure adjustments up to 15 MPa via the hydraulic mechanism, ensuring optimal threading force and efficiency.Q: Where can this machine be effectively used?

A: The portable, wheeled design allows the machine to be deployed at various construction sites, fabrication shops, or any location needing bar threading for reinforcing steel. Its export-standard wooden box packing ensures safe transport to distant sites.Q: What is the process for threading bars using this machine?

A: The process involves securing the bar with the clamp set, selecting the appropriate threading die, and operating the machine through the manual or electric panel. The automatic lubrication system maintains smooth operation while the bar is threaded at the set main shaft speed.Q: How does the machine ensure precision in threading?

A: Precision is maintained with a main shaft speed of 62 rpm and an accuracy rating of 0.1 mm. The reliable clamping system and rigid welded frame provide further consistency in every threaded bar.Q: What are the primary benefits of using this threading machine for construction projects?

A: Users gain from its heavy-duty build, portability, fast setup, and low operational noise. The machines adaptable design, safety features, and user-friendly control system streamline the reinforcement bar threading process, increasing productivity and safety on construction sites.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Threading Machines Category

Bolt Threading Machines

Cooling System : Integrated water cooling

Frequency : 50 Hz

Machine Type : Threading Machine

Usage & Applications : Threading of bolts, rods and fasteners

Frame Type : Rigid steel frame

Noise Level : <75 dB

Scaffolding Pipe Threading Machines

Cooling System : Air Cooling

Frequency : 50/6 Hetrz (Hz)

Machine Type : pipe threading machine

Usage & Applications : Industrial

Frame Type : Metal Frame

Noise Level : low db

Electric Conduit Pipe Threading Machine

Cooling System : Air Cooling

Frequency : 50/6 Hetrz (Hz)

Machine Type : steel bar threading machine

Usage & Applications : Industrial

Frame Type : Metal Frame

Noise Level : low db

PVC Pipe Threading Machines

Cooling System : Air Cooling

Frequency : 50/6 Hetrz (Hz)

Machine Type : pipe threading machine

Usage & Applications : Industrial

Frame Type : Metal Frame

Noise Level : low db

GST : 03BXNPS2799K1ZN

|

INDUSTRIAL MACHINERY CORP.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry